Guangri Winding Machine: Pioneering Precision in Modern Winding Technology

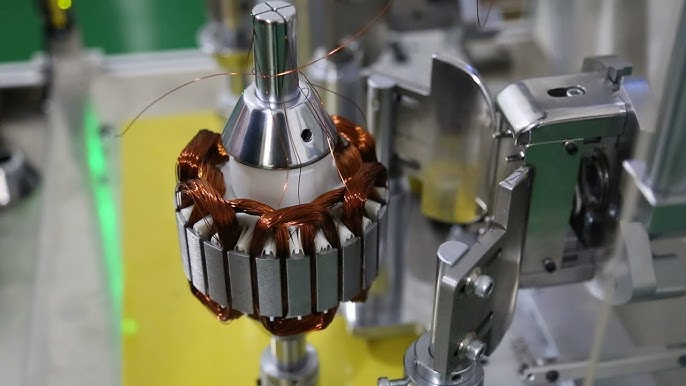

As the demand for higher efficiency, precision, and automation continues to reshape manufacturing industries, winding technology has undergone a significant transformation. Among the forefront innovators is Guangri, a trusted name known for delivering state-of-the-art winding machines that combine robust engineering with intelligent automation. From the production of electric motors to transformers, Guangri winding machine are redefining productivity across diverse sectors.

Evolution of Winding Technology

Winding technology has evolved from manual spool winders to highly automated, computer-controlled machines capable of complex winding patterns. This evolution reflects a broader industrial shift toward Industry 4.0, where smart technologies, data analytics, and precision engineering intersect.

Key milestones in winding technology evolution include:

- Manual to Automated Winding: Early machines required significant human input. Today’s CNC-controlled winders, like those from Guangri, can execute thousands of turns with micron-level precision.

- Material Handling Advancements: Modern winders accommodate a wide range of wire materials—from copper and aluminum to specialized alloys—enhancing compatibility across industries.

- Smart Monitoring Systems: Integrated sensors and software monitor parameters like tension, wire breakage, and winding angle in real time, reducing waste and downtime.

Guangri’s Technological Edge

1. Advanced Winding Techniques

Guangri winding machines utilize cutting-edge techniques such as:

- Multi-layer Precision Winding: Ensures uniform distribution and compact coil formations, especially crucial in transformer and inductor manufacturing.

- Toroidal and Segment Winding: For applications requiring high energy density and space efficiency.

- Automatic Wire Tension Control: Guarantees consistent coil quality regardless of wire diameter or type.

- High-speed Interleaved Winding: Prevents electrical interference and overheating by evenly spacing windings.

2. Industry-Specific Applications

Guangri machines are engineered for versatility, with tailored models serving various high-demand sectors:

- Automotive Industry: Used in the production of EV motors, ignition coils, and sensors.

- Power and Energy: Winding machines for transformers, inductors, and power electronics ensure durability and high-performance efficiency.

- Consumer Electronics: Compact winding systems for mobile components, speakers, and wireless charging coils.

- Medical Devices: Micro-winding capability for compact, high-precision components like micro-motors and diagnostic sensors.

3. Automation and Customization

Guangri integrates PLC (Programmable Logic Controllers) and HMI (Human-Machine Interfaces) into their machines, offering:

- User-friendly operation

- Custom winding patterns

- Real-time diagnostics and remote troubleshooting

- Integration with MES (Manufacturing Execution Systems) for data traceability

Some of their models even offer robotic arm integration for fully automated coil loading/unloading, making them ideal for mass production lines.

Sustainability and Efficiency

With environmental standards tightening globally, Guangri’s machines also emphasize energy efficiency and material optimization. Their precise wire placement and reduced material wastage align with green manufacturing initiatives while lowering overall production costs.

Looking Forward: The Future of Winding with Guangri

As industries continue to push the boundaries of electric and electronic design—particularly with the rise of electric mobility, smart grids, and IoT-enabled devices—Guangri is poised to lead the next chapter of winding technology. Innovations such as AI-assisted predictive maintenance, digital twins, and fully modular winding platforms are on the horizon.

Conclusion

Guangri winding machines exemplify the convergence of tradition and innovation in modern manufacturing. By harnessing advanced winding techniques, customizing machines for industry-specific needs, and continually evolving their technology, Guangri continues to empower manufacturers with precision, scalability, and reliability. Whether you’re building the next generation of electric vehicles or microelectronic devices, Guangri offers the winding solutions to keep you ahead of the curve.